For many, woodworking is a wonderful pastime that provides a very rewarding creative experience. The tactile process of transforming wood into beautiful and functional objects can capture the mind and heart for a weekend or a lifetime. Still, woodworking safety is a critical concern.

As with many activities, woodworking does include a certain level of exposure to harm. The good news is, minimizing and even eliminating opportunities for injury is relatively easy. Common sense, good practice and an understanding of materials and processes can go a very long way to keeping you safe and helping you enjoy this hobby so many of us have come to love.

Practice Good Habits

Safety is a priority. And good habits keep it a priority, even when you might be a little more complacent than is optimal. Establishing and following a set of personal rules that you never deviate from – not even for a “it’s just one quick cut” moment – will pay dividends.

Determine some things that you always do (or never do). Always wearing appropriate safety equipment. Never operating machinery after you’ve been drinking. Forcing patience, regardless of being under whatever self-imposed deadline you find yourself. Define your own personal code of shop conduct and be true to it. This fundamental rule alone can stave off a lot of opportunities for disaster.

Dress Appropriately

Safety begins before you even step into the shop. What are you wearing? Loose clothes can get caught on any number of things – a stack of lumber or a can of finish; or, even worse, a spinning blade. Reduce the chances of accidents by keeping your attire as form-fitting as you can comfortably work in.

And comfort is important, too. If you’re too cold, you’re going to expose yourself to other potential accidents or mistakes. However, if given the choice, short sleeves will always be a better choice than long.

The risk of snagging isn’t limited exclusively to clothing. Jewelry and hair can get caught on edges or in spinning arbors. Remove your jewelry and tie back longer hair before getting to work.

Things have a tendency to fall in workspaces. Obviously, that’s not the plan, but things happen. And when they do, you want to make sure your feet are protected. Never wear open-toed shoes and, when possible, select footwear that can withstand a misstep onto something sharp. Most of all, avoid any footwear that creates a slip and fall hazard.

A Safe Shop

The environment in which you work has a large influence on how safe a space it is. Keep your shop as brightly lit as possible (I’ve yet to work in a shop that was “too bright”). Employ task lighting for shadowed areas. Not only will your overall experience be more enjoyable, you’ll find it easier to perform more precise tasks by making everything easier to see.

Woodworking can be dangerous to lungs, too. Sawdust is an irritant (or worse, depending upon the species). Chemicals for finishing and some adhesives are dangerous to inhale. Make sure your shop is properly ventilated and use dust collection solutions that equal your needs.

A couple of safety items are requisite as well. Keep a dedicated fire extinguisher handy (hopefully, you’ll never need to use it), as well as a first aid kit (let’s not kid ourselves – you’ll most definitely use it).

Clutter is one of the most common dangers in a typical woodshop. The best approach is to stay on top of things by getting into the habit of always cleaning up, putting away and organizing your space between major tasks and at the end of every woodworking session. Besides, working in a clean, well-organized shop is just downright more pleasant.

Keeping Machines Safe

A shop is basically a giant toolbox filled with objects that have been optimized for cutting. Rendering those tools a safe as possible has to be a top priority.

For power tools, keep them unplugged unless they are in active use. Most woodworkers work alone. Ideally, there should only be one tool plugged in at a time. This is particularly important in shops that have child visitors (such as an in-home shop for a family with children). Kids like pressing buttons. In all cases, when you’re closing up for the day, take a quick pass and make sure everything is unplugged before turning out the lights.

Most, if not all, power tools come with a user manual. The first few pages of safety guidelines as written by lawyers can be tedious and easy to skip over. However, sometimes these notes contain a key piece of information that can keep you safe or extend the life of the tool (often both). Get into the habit of spend an extra five minutes reading these warnings and guidelines. The rest of the manual is not just to keep you safe (and them from being sued), but also to maximize the chances of you getting the best results from the tool. After all, it’s in the manufacturers’ best interests that you have a lot of success with their product and hopefully recommend it to your friends. Fight the urge to believe you already know all there is to know and give the instructions a fair reading.

Many machines are packaged with safety gear. It’s not uncommon for these items to be discarded or ignored. We’re asking that you don’t. The guards, shields and other devices included could be the only thing keeping you from a serious injury. Use them. Again, our rule is good habits. Could we make the cut without the blade guard in place? Sure. Could we perform that operation 1,000 times without incident? Quite likely. But would having it in place every time reduce or eliminate the opportunity to lose a finger? Some costs are simply too high. Forcing yourself to use safety devices every time, no matter what, puts you in a much safer place over the course of your woodworking.

Additionally, there are many jigs and fixtures that can be purchased after-market or built in your shop. These items are frequently designed to make operations more accurate or to prevent accidents. Research your tools and the available devices that can help you get the most from them.

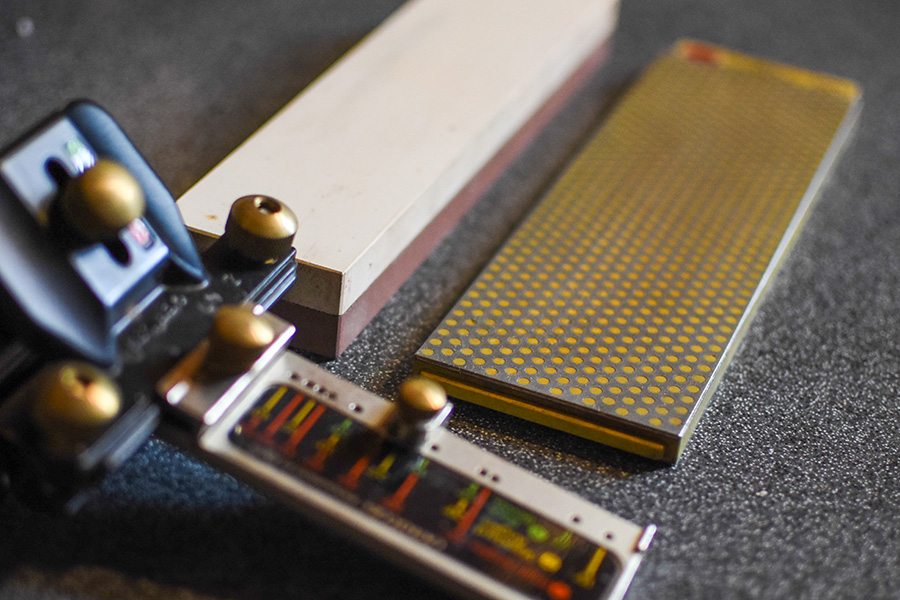

Sharpen Your Tools

A dull tool is an accident waiting to happen. They don’t perform in an optimal or predictable manner. They require additional force. Simply put, the duller the blade, the higher the risk. Determine the best practices to keep each tool sharp before putting it to use and keep them in that state, whether that means acquiring appropriate sharpening tools and developing a habit of keeping the edges keen or finding a seasoned smith to tend to your blades when they begin to lose their edge.

Inspect Your Material

Always check your lumber before begin any milling process. The first step is to look over all of the surfaces and edges of wood you have chosen to work. Loose knots can tear free and become a flying hazard. Remove them during the bust-down step to avoid this risk. Reclaimed wood can be (and often is) hiding old nails, screws or other bits of metal. A few rare earth magnets attached to a string or fishing line waved over the lumber can detect the presence of hidden dangers before they become a bigger problem.

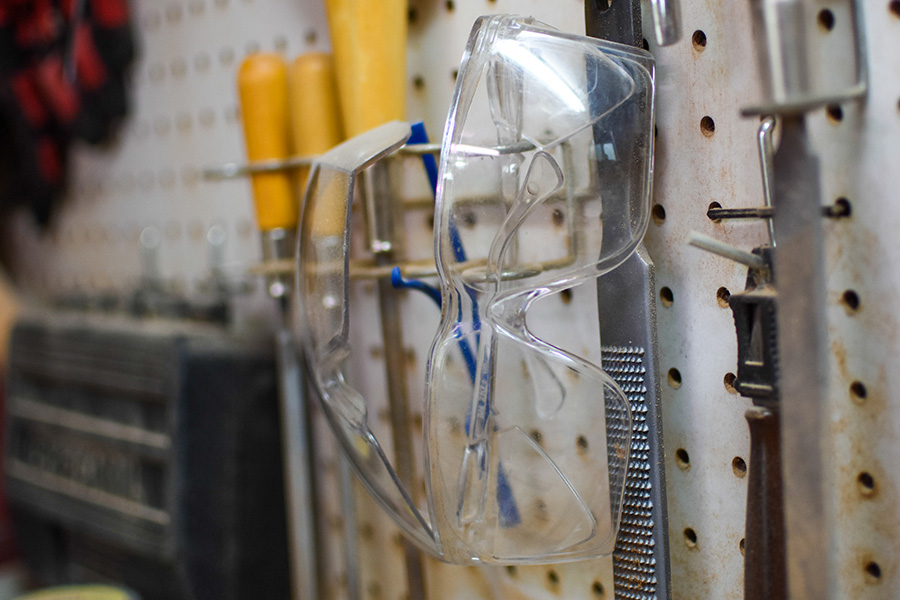

Use Safety Gear

Hearing, eye and respiratory protective devices (commonly referred to as “personal protection equipment” or “PPE”) is mandatory in a safe shop. We opt for OSHA-approved devices and then do a little research on what options best suit our woodworking tasks. For example, different tools will require differing levels of decimal reduction to be hearing safe. We know what equipment is needed for each tool and wear them every time that tool is operated.

Rules of Thumb

Other than being disciplined with our habits, there are a few other general rules we follow that have been created with overall comfort and safety in mind.

-

If an operation feels unsafe, it probably is. Trust your gut and think of a better way to make a particular cut. Sometimes that requires spending an hour or so making a special jig for the task. It’s far better to add a few extra steps than to suffer a serious injury.

-

Reduce risk by limiting exposure. If an operation can safely be performed in one pass, don’t use two. The fewer times your hands pass near the cutters, the fewer opportunities for something to go wrong.

-

Limit distractions. Some low-risk task can be performed under all sorts of circumstances. Others cannot. Don’t attempt to carry on a conversation with someone while making dangerous cuts. Turn the music down or the podcasts off for tasks that require extra concentration. Avoid surprises (can someone walk into your noisy shop and come up behind you unaware?).

-

Never reach over a cutter in motion. Wait until the blade comes to a complete stop.

-

Always position your body to be outside of the cutting path of stock being machined. Kickback is a common and serious risk in woodworking.